Introduction

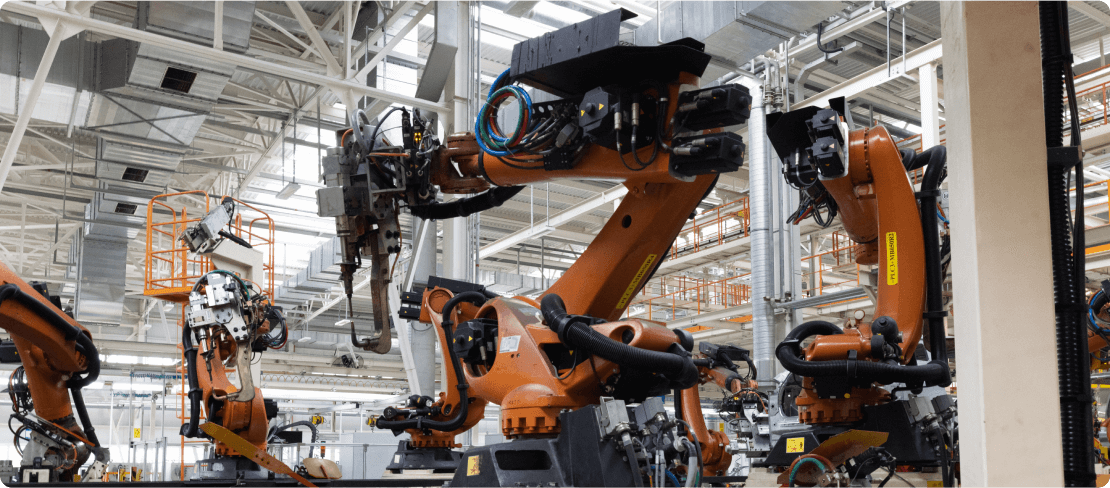

Lights-out manufacturing is a transcending and next-generation technology with completely automated manufacturing processes, producing goods at factories with minimal human intervention. This disruptive manufacturing trend infuses Artificial Intelligence, Machine Learning, and automation tools to optimize and streamline production processes. Artificial Intelligence helps to identify the pattern, while Machine Learning provides predictive maintenance to respond to anomalies and increase speed and efficiency. Lights out manufacturing nullifies workplace accidents and boost safety.

Actors

01

Manufacturing Firm / Factory

The place where goods are getting manufactured automatically.

02

Factory Floor Manager

Oversees and manages production operations, including critical decision-making.

03

AI and ML Solution Tools

Advanced AI ML development services help extract and analyze real-time data, suggesting ways to optimize lights out manufacturing.

Preconditions

Setting up Lights-out Manufacturing Infrastructure

The vital components of the Lights out manufacturing include automatic material management, robotics, IoT sensors, centralized and quality control systems, energy utility solutions, etc. All these crucial elements and advanced systems automate processes without human intervention, helping to establish a lights out manufacturing infrastructure.

Availability of Real-Time Data

Factory managers and key decision-makers can access large volumes of real-time data to identify the machine behavior, downtime instances, maintenance updates, quality metrics, and more. The essential data trains Machine Learning modules and encompasses the patterns.

Data Gathering Software

The factory implements advanced data-gathering tools and mechanisms with complete sensor networks, capturing real-time insights on machine performance and energy consumption processes.

Post Conditions

Improved Operational Efficiency

AI ML development services allow factories to enhance operational efficiency and production output without increasing resources.

Mitigate Downtime Issues

The Lights Out manufacturing uses predictive maintenance to eliminate downtime by sending maintenance alerts in advance and scheduling production.

Ensure Optimal Product Quality

Lights Out Manufacturing aims to optimize product quality consistently by mitigating all production barriers and promptly addressing issues.

Best Resource Optimization

AI and ML systems help to allocate resources in the best possible way and utilize them based on real-time demands and production patterns.

Minimal Human Interference

Artificial Intelligence and Machine Learning systems automate operations, decision-making, and optimization to nullify human interference.

Continuous Learning and Improvement

AI and Machine Learning tools continuously learn from new data sets to adopt the best recommendations and innovative models. The learning makes the system much more efficient and accurate in predicting the results and identifying loopholes.

Main Flow

Alternative Flow

- Detecting a Glitch in Machine Function - If the AI/ML development services detect any fault or anomaly in the machine's behavior or functioning, it leads to production halts and delays. Factory managers and technicians are altered to resolve the issue immediately, ensuring safety and quality standards are maintained.

- Manual Process - During an unusual situation, the factor manager has to switch to a manual production process with full human intervention as automation fails to occur as expected. The AI tools have to adjust to manual operations and show results accordingly.

- Continuous Improvement - Since AI/ML solutions continuously learn from new data, improving product quality and the factory’s overall operational efficiency and performance is helpful.

Conclusion

The convergence of AI/ML development services with intelligent lights out manufacturing has brought a mechanical evolution and holistic transformation in how products are produced, delivered, and utilized. The infusion propels to achieve unprecedented operational efficiency, cost-effectiveness, and unmatched product quality.

Suggested TechStack

Industrial robots have become one of the critical components of lights-out manufacturing efficiently automating material management, assembly, and packaging. CAD software supports these advanced systems, and a centralized computer system controls them.

AI/ML development services integrate with IoT sensor data, analytics, and connectivity to automate and streamline manufacturing operations. They are also involved in real-time monitoring, predictive maintenance, and process optimization.

Edge computing helps minimize manufacturing process latency by integrating data in centralized servers or the cloud. Managers leverage real-time insights to make informed decisions.

Empowering Industry with AI and ML-Driven Automation for Enhanced Efficiency and Quality!

Pioneering the Future of Manufacturing: Step into Lights-Out Factories