Introduction

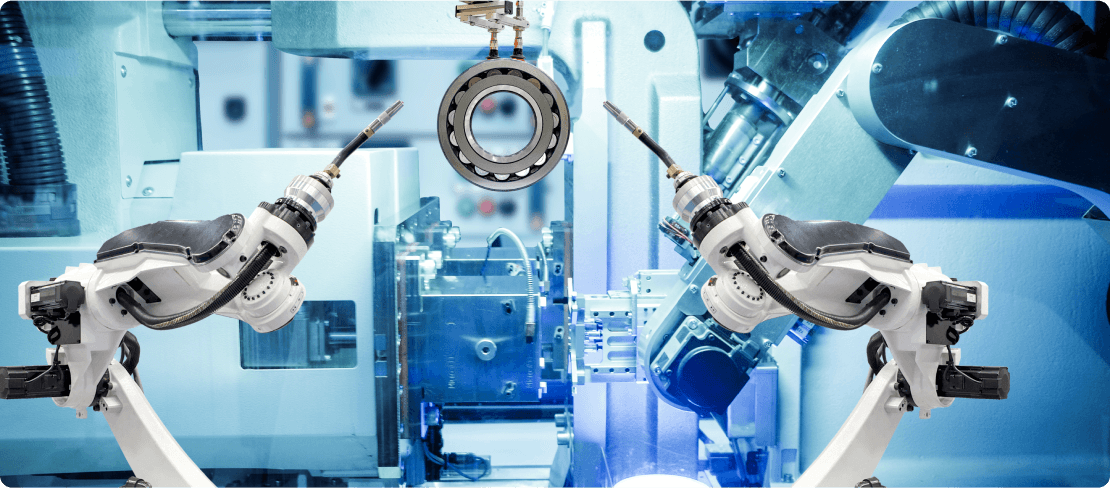

Robotic Process Automation (RPA) is one of the extensive and popular use cases of Artificial Intelligence and Machine Learning in the manufacturing industry. RPA in manufacturing brings several benefits, such as minimizing the overall operational cost, improved productivity, better product design and quality, and faster decision-making abilities.

Actors

01

The Manufacturing Firm

It is responsible for overseeing and managing the entire manufacturing process.

02

RPA Bot

It is an automated, advanced software tool with AI/ML capabilities.

03

Quality Control Manager

They analyze production reports, identify recent trends, and create strategies to drive continuous improvement using AI/ML.

Preconditions

Manual and Repetitive Tasks

The manufacturing process involves a significant portion of manual and repetitive tasks that can be automated.

Accessible Digital Data

Necessary data related to manufacturing operations is digitally accessible and available.

Defined Decision Logic

The decision logic involved in manufacturing processes is well-defined and can be translated into AI/ML-enabled decision-making algorithms.

Stable IT infrastructure

RPA in manufacturing combined with AI/ML development services is integrated into manufacturing software development.

Process Understanding

The manufacturing operators and the development team clearly understand the existing processes and how automation can be integrated.

Post Conditions

Streamlined and Optimized Operations

Integrating RPA in manufacturing with AI/ML development services has led to seamless, more streamlined, and optimized manufacturing operations.

Human Error Reduction

The implementation has significantly minimized human errors, enhancing product quality and consistency.

Enhanced Data Insights

The AI/ML analysis of manufacturing software development data has provided deeper insights into process trends, allowing for data-driven optimization.

Adaptability and Scalability

The RPA in manufacturing can be easily adapted to new processes or scaled to handle increased production demands.

Faster Decision-Making

AI/ML-enabled bots make informed decisions in real-time, leading to quicker adjustments and responses to changes in the manufacturing environment.

Operational Cost Savings

Reducing manual labor and errors has resulted in substantial cost savings related to rework, waste, and operational inefficiencies.

Main Flow

Alternative Flow

- Handling Exceptions - If the RPA bot develops an issue or faces an unexpected situation, it comes under an exception.

- Resolving the Exceptions - Once the manufacturing operator receives an alert regarding an exception, he reviews the condition, decides, and propels the RPA bot on how to proceed further.

- Learning the Exceptions - The RPA bot gains knowledge and insights about the new exception. It integrates its resolution process into its AI/ML algorithms to avoid similar instances in the future.

Conclusion

Implementing AL and ML-powered RPA in manufacturing has automated and streamlined the process and led to intelligent decision-making, enhancing the quality of manufactured products.

Suggested TechStack

RPA in manufacturing are next-generation software solutions that automate processes and stimulate digital transformation. It allows developers to create RPA bots using Natural Language Processing, Artificial Intelligence, and Machine Learning algorithms. The most popular RPA tools are UiPath, Automation Anywhere, and Blue Prism.

AI and ML frameworks are crucial for creating and training neural networks and scalable, dynamic computed graphs. The frameworks provide advanced data mining and analysis tools and optimize machine learning models.

A robust and efficient database is necessary to store critical data, such as production logs and quality metrics. It also handles structured and unstructured data like sensor readings and log files.

Discover How RPA and AI/ML Fusion Enhance Efficiency, Quality, and Agility

Empower Your Manufacturing with AI-Driven RPA