Software modernization involves unlocking the benefits of robust cloud infrastructure and computing solutions through microservices architecture and Kubernetes. Microservices architecture allows organizations to accelerate the speed of software development and deployment, while Kubernetes enhances scalability, reliability, and cost-efficiency.

An Introduction to Software Modernization in Manufacturing Operations

Software modernization is the process of upgrading, optimizing, and re-architecting a legacy system to enhance its overall efficiency, usability, performance, and security. Software modernization overhauls and revitalizes an outdated system to harness newer digital trends and futuristic technologies.

The transformation amplifies scalability, resilience, and flexibility, ensuring the solution meets evolving business demands. It is a critical enabler of innovation, competitiveness, and operational excellence.

Software modernization has played various pivotal roles in diverse industry verticals. Now, if we talk about its significant contribution to the manufacturing industry, it is the facilitation of Industry 5.0 initiatives.

The manufacturing hub is ready to embrace next-generation technologies like Lights-out Factory, Digital Twins, and Robotic Process Automation to automate the production process with minimal human intervention. They can extract and access real-time data and historical insights to derive meaningful metrics, driving informed decisions.

Advanced software systems also pave the way for streamlining and improving the different elements of the manufacturing process, such as inventory management and supply chain handling. The up-to-date software provides precise and real-time information on stock levels with better visibility and control over their supply chains.

This functionality is critical for manufacturing entities that depend on the accurate time of materials and components. It also enhances the response times to fluctuations in the market and customer demands, allowing manufacturers to remain competitive.

Software modernization becomes paramount to address cybersecurity concerns. Old and outdated systems are more vulnerable and may be unable to protect data from advanced cyber attacks. Also, they may not comply with the latest security compliance and regulatory requirements.

- Introduction

- The Relevance of Microservices Architecture and Kubernetes

- The Core Challenges of Traditional Software

- Software Modernization is the Need of the Hour

- Let’s Understand Microservices Architecture

- An Introduction to Kubernetes

- Implementing Microservices and Kubernetes in Manufacturing

- Enhancing Manufacturing Operations with Modern Software Solutions

- Challenges and Solutions in Software Modernization

- Conclusion

The Relevance of Microservices Architecture and Kubernetes

Microservices architecture and Kubernetes are transforming the manufacturing industry by increasing operations' agility, resilience, flexibility, and scalability.

Microservices architecture breaks down the application into small independent services. Developers can create, deploy, and scale them individually. This modularity is particularly beneficial in manufacturing environments that require high adaptability and rapid iteration to meet dynamic market demands.

Let’s explain this with an example.

Suppose, a manufacturing unit wants to separate its inventory management, production scheduling, and quality control systems. It can do so quickly and efficiently using microservices, which scale and update each service independently.

How Does It Benefit the Manufacturing Industry?

- Microservices architecture allows quickly respond to changes in demand or production needs without disrupting the entire system.

- The granularity level ensures that every aspect of the process is optimized and adjusted appropriately to enhance operational efficiency.

Kubernetes, on the other hand, is an open-source container orchestration platform that helps to orchestrate, containerize, and manage the services across a distributed environment.

It automates deployment, scaling, and operations of application containers, ensuring efficient use of resources. It also complements microservices by managing containerized applications at scale.

Let’s Give an Example Here to Illustrate Things Better.

Suppose a manufacturer utilizes the Internet of Things (IoT) device to monitor machine performance. Microservices manage data gathering, processing, and analytics separately, On the contrary, Kubernetes, ensures their smooth and constant running, helping them to upscale their incoming data volume.

How Does It Benefit the Manufacturing Industry?

- Kubernetes streamlines the software deployment process and provides real-time updates across the production line.

- It allows developers to release new features or patches quickly and consistently, reducing the risk of downtime and improving overall system reliability.

- It leverages predictive analytics to address potential issues before they cause significant disruptions.

- Kubernetes facilitates load balancing and self-healing.

The Core Challenges of Traditional Software

Outdated Systems - Outdated systems that are difficult to upgrade. These legacy systems often lack the flexibility needed to adapt to modern production demands and integrate new technologies, leading to inefficiencies and increased maintenance costs.

Interoperability - In a diverse manufacturing environment, different systems and software must communicate seamlessly. However, traditional manufacturing software often struggles with interoperability, leading to data silos and inefficient workflows. This lack of integration hinders comprehensive data analysis and real-time decision-making.

Costs and Resource Limitations - Upgrading or replacing traditional software can be prohibitively expensive. Small and medium-sized manufacturers, in particular, face financial and resource constraints, making it challenging to invest in new technologies and maintain competitive operations.

Skill Gap and Workforce Readiness - Workers trained on traditional systems may lack the expertise needed to operate and maintain modern, sophisticated software, hindering the adoption of innovative solutions.

Change Management - Transitioning from traditional to modern manufacturing software involves significant organizational change. Resistance to change, coupled with the need for extensive training and process re-engineering.

Cybersecurity - Traditional manufacturing software is often vulnerable to cyber threats due to outdated security measures. As manufacturing systems become increasingly connected, the risk of cyberattacks grows, potentially leading to data breaches and operational disruptions.

Software Modernization is the Need of the Hour

Implementing and utilizing software modernization services can help resolve all the above-mentioned issues and empower manufacturers to harness the benefits of microservices architecture and Kubernetes at the same time.

Streamlined and Real-Time Data Gathering

Modern software solutions allow to store data more efficiently in a centralized location. Software modernization uses cloud infrastructure to collect real-time data automatically and generate detailed reports. Hence, manufacturers can hire AWS developers to leverage cloud services for data collection and improved analytics.

We can cite the example of IoT and AI-powered analytics, letting manufacturers predict equipment failures and schedule maintenance proactively, avoiding costly breakdowns.

Increased Efficiency and Productivity

Modern and advanced software systems automate and streamline different manufacturing operations, minimizing manual intervention and mitigating human errors. It leads to accelerated production cycles, optimized resource utilization, and improved overall productivity.

Here, we can illustrate software modernization’s role in ERP systems that automate inventory management, reducing stockouts and overstock situations, thus ensuring smooth production flow.

Improved Flexibility and Scalability

Modern software architectures like cloud computing and microservices provide enhanced flexibility and scalability. Manufacturers can easily adapt to changing market demands and scale their operations without significant overhauls.

Improved Integration and Interoperability

Modern software solutions are designed to integrate seamlessly with various systems and ensuring smooth interoperability. This eliminates data silos and enhances overall collaboration.

For example, manufacturers can integrate supply chain management software with production planning systems to optimize and automate the procurement process and logistics, establishing improved coordination between them.

Fortifying Cybersecurity

Enhanced cybersecurity is the backbone of modern software applications where our developers focus on providing regular updates, implementing data encryption, user authentication, and access control to protect against cyber threats and safeguard sensitive manufacturing data.

Let’s Understand Microservices Architecture

Search Engine Giant Google Defines Microservices Architecture as -

“A type of application architecture where the application is developed as a collection of services. It provides the framework to develop, deploy, and maintain microservices architecture diagrams and services independently.”

Microservices architecture breaks down the complex architecture and applications into smaller manageable components to simplify maintenance, scalability, and updates. Each of the services operates separately and well-defined APIs help to establish robust communication between teams for working simultaneously.

The modular design of this architecture streamlines the addition of new features or modifications to existing ones. Additionally, microservices promote fault isolation, as failures in one service do not necessarily impact others, enhancing the overall robustness and resilience of the application ecosystem.

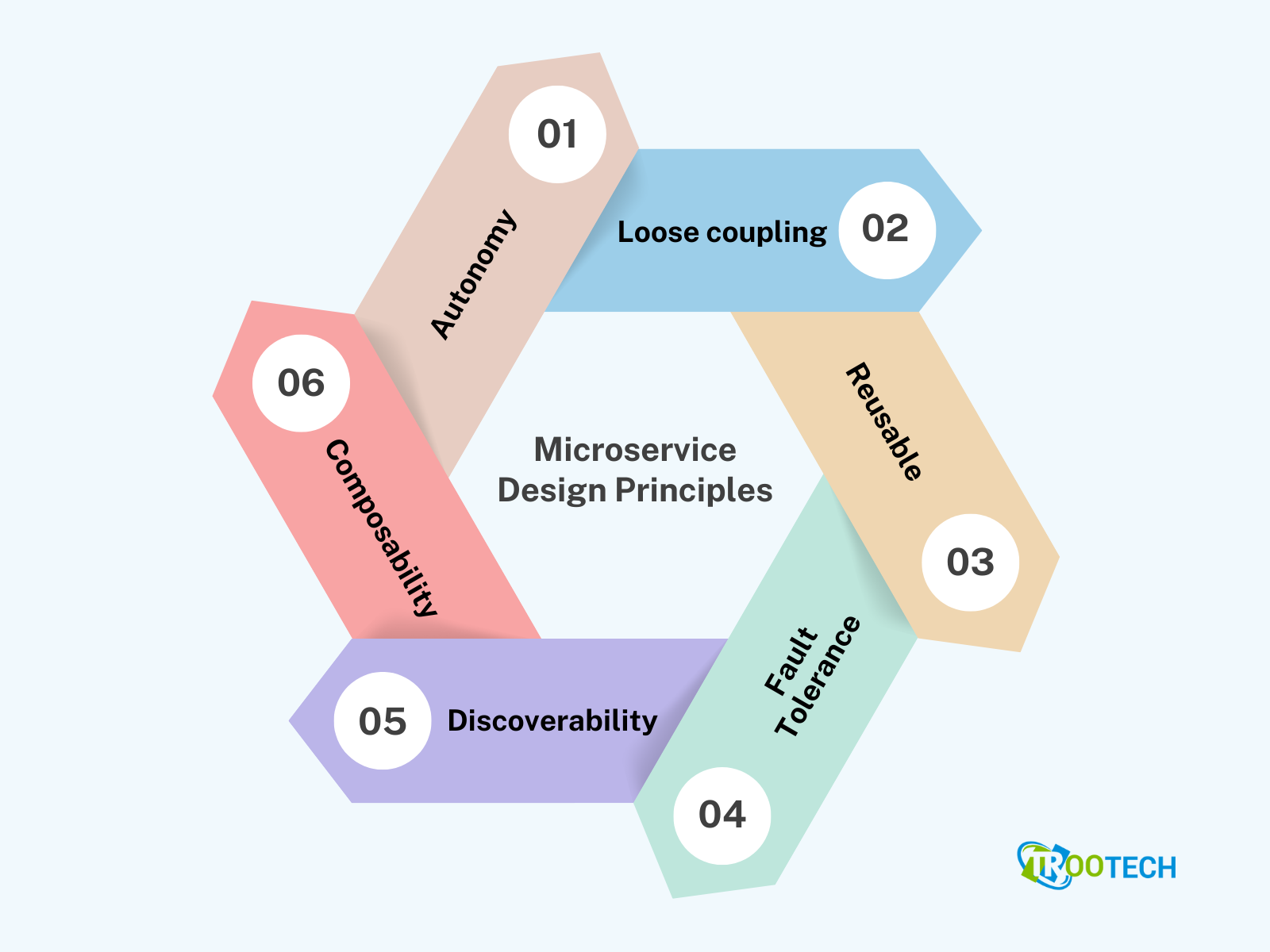

6 Core Microservice Design Principles

Autonomy: Every microservice should be self-contained and operate independently of other services in an application. Each service should have its own resources, including separate databases and business logic, to perform its functions without relying on other services. This independence allows for isolated development, deployment, and scaling processes, fostering rapid iteration and innovation.

Loose coupling: Maintaining loose coupling between microservices is generally considered a best way in a microservices architecture. This principle ensures that changes or updates to one service do not impact others, facilitating simpler maintenance and seamless integration.

Reusable: Each microservice should be developed with reusable code and functionality that can be leveraged across different services. This approach allows developers to efficiently build upon existing components, promoting consistency and accelerating development efforts across the system.

Fault Tolerance: Each microservice should be inherently fault-tolerant to minimize the impact of failures in collaborating services. Being independent, microservices should be able to isolate and handle failures gracefully. This independence allows them to mitigate disruptions by terminating communication with failed services and maintaining overall system reliability.

Discoverability: In microservices architecture, it's crucial to implement service discovery mechanisms to facilitate dynamic location and communication between services within the development ecosystem. Tools like Eureka or Consul are commonly used to achieve this, ensuring seamless integration and interoperability.

Composability: Applications in microservices architecture should prioritize composability, allowing for the development of complex systems by combining modular services. This approach enables developers to treat services as building blocks, assembling them to tailor solutions to specific business needs.

Benefits of Microservices Architecture

Promotes Modular Development:

Microservices enable the development of discrete, independently deployable services. It allows developers to build each component of a manufacturing software as a standalone service. For example, inventory management, order processing, and quality control can all be separate services.

It facilitates rapid development, testing, and deployment cycles. Since services are independent, developers can work on and deploy updates to a single service without impacting the entire system. This accelerates the development lifecycle and reduces downtime during updates.

Enhanced Scalability:

Microservices architecture enhances scalability by allowing individual services to independently scale based on demand. For instance, high-demand services like order processing can scale up without affecting other services. This targeted scalability optimizes resource utilization and reduces costs by avoiding over-provisioning. Manufacturers benefit from cost savings as they efficiently allocate resources to meet specific service demands.

Increased Resilience:

Our developers also saw that it isolates faults within specific services, minimizing system-wide failures. If a bug or failure occurs in one service, it doesn't bring down the entire application. This isolation improves the overall system's stability.

It enhances system reliability and uptime. With microservices, the failure of one component can be handled gracefully without significant disruption, ensuring continuous operations.

Greater Flexibility:

Microservices in manufacturing management software development support diverse programming languages and technologies for different services. The development teams can choose the best technology stack for each service, allowing for optimal performance and innovation.

Our developers found it relatively easier to implement new features and technologies. As new technologies emerge, they can be integrated into the architecture without major overhauls, ensuring the system remains modern and competitive.

Improved Collaboration

Microservices in manufacturing management software development support diverse programming languages and technologies for different services. The development teams can choose the best technology stack for each service, allowing for optimal performance and innovation.

Our developers found it relatively easier to implement new features and technologies. As new technologies emerge, they can be integrated into the architecture without major overhauls, ensuring the system remains modern and competitive.

Examples of Microservices in Manufacturing

Microservices architecture has several useful applications in the manufacturing industry. A few notable ones include

- Inventory Management - Helps to track stock levels, reorder products, and manage warehouse inventory.

- Production Scheduling - Dynamically adjusts production schedules based on real-time data insights

- Quality Control - Automates inspection process using machine learning to analyze data and identify defects in quality standards.

- Supply Chain Management - Efficiently manage supply chain operations, supplier interactions, order tracking and logistics.

- Customization and Order Processing - Handle customer-specific requirements and configure production parameters accordingly.

Looking to Implement Cloud and DevOps-Based Features for Your Hospitality Business?

Enhance Guest Experiences and Streamline Operations with Cutting-Edge Cloud Solutions

An Introduction to Kubernetes

If we have to define Kubernetes in simple layman's terms, it is an open-source container orchestration software that automates, scales, and efficiently manages the software deployment process. Kubernetes, also known as K8s, was originally developed and is maintained by Google with an active community of contributors and developers worldwide.

Kubernetes automates container management tasks and includes built-in commands to deploy applications and roll out the changes, enhancing flexibility capability. It means you can make your application scalable and customizable to fit changing needs and monitor it easily and quickly.

How Kubernetes can be applied in the manufacturing business:

1. Optimizing Production Line Management:

- Dynamic Scaling: Kubernetes can manage the scalability of applications that monitor and control production lines, ensuring that resources are efficiently allocated based on real-time demand.

- Microservices Architecture: Implementing a microservices architecture for production management applications allows for independent updates and scaling, reducing downtime and improving reliability.

2. Improving Supply Chain Management:

- Automated Deployments: Kubernetes can automate the deployment of supply chain management applications, ensuring they are always running the latest versions with minimal manual intervention.

- Data Analytics and Processing: Kubernetes can manage big data processing applications that analyze supply chain data, providing insights to optimize inventory levels, forecast demand, and streamline logistics.

3. Enhancing Quality Control:

- Machine Learning Models: Deploying machine learning models on Kubernetes can help in predicting defects and maintaining quality control. These models can be continuously trained and updated without disrupting the manufacturing process.

- Real-time Monitoring: Kubernetes can handle applications that perform real-time monitoring of product quality, allowing for immediate response to any issues detected during manufacturing.

4. Streamlining Maintenance Operations:

- Predictive Maintenance: Applications that predict equipment failures based on sensor data can be deployed on Kubernetes, enabling proactive maintenance and reducing downtime.

- Remote Monitoring: Kubernetes can manage applications that enable remote monitoring and diagnostics of machinery, facilitating quick troubleshooting and maintenance.

5. Facilitating IoT Integration:

- Edge Computing: Kubernetes can manage applications running on edge devices within a manufacturing plant, processing data locally to reduce latency and bandwidth usage.

- Device Management: Kubernetes can handle the deployment and management of software updates to IoT devices, ensuring they are secure and up-to-date.

6. Supporting Research and Development:

- Simulation and Modeling: Kubernetes can manage applications that perform simulations and modeling of manufacturing processes, helping in the development of new products and processes.

- Collaborative Platforms: Kubernetes can deploy collaborative platforms that allow R&D teams to work together seamlessly, sharing data and resources efficiently

Implementing Microservices and Kubernetes in Manufacturing

Before implementing Kubernetes and Microservices, you must ensure that you are using monolithic architecture. If you are then the first step is migrating from monolithic to microservices architecture.

Here we will guide you through the step-by-step process of transiting from monolithic to microservices architecture.

Step 1: Assessment and Planning - Understand and analyze your current system to prepare a comprehensive documentation of monolithic architecture, including dependencies, workflows, etc. to identify the existing pain points and resolve them.

Step 2: Creating the Architecture Design: Our system architects and DevOps engineers create microservices architecture by defining each microservice based on business capabilities, selecting the appropriate technology and containerization platforms, designing APIs, and establishing communication patterns.

Step 3: Implement Infrastructure - You need to establish DevOps practices by integrating CI/CD pipelines to automate testing and deployment. Use IaC tools like Terraform or CloudFormation to manage infrastructure.

Step 4: Develop and Migrate - Choose a non-critical service as a pilot for migration, refactor the chosen monolith, decompose the monolithic architecture, and implement necessary communication mechanisms between microservices and the monolith during the transition.

Step 5: Meticulous Testing - Conduct automated testing for each of the microservices architecture, such as unit and integration. Also, utilize the mock services to enhance interactions with other microservices. Perform load testing to check whether the microservices can handle expected traffic, and monitor and optimize the latency of inter-service communication.

Step 6: Deployment and Scaling - Use blue-green deployments to minimize downtime and implement canary releases to roll out new changes. Scale microservices horizontally using orchestration tools and ensure each microservice has appropriate resource allocation to handle peak loads.

Step 7: Continuous Improvement - Gather feedback from developers and users continuously to identify areas for improvement and regularly iterate on the microservices architecture to enhance performance, Reduce technical debt by periodically refactoring microservices and updating dependencies.

Best Practices to Deploy Kubernetes in Manufacturing

We share the best practices for deploying Kubernetes architecture for microservices in the manufacturing industry.

Scaling Up the Applications - Upscaling the apps based on the demand helps to enhance manufacturing efficiency.

Implementing Robust Security - One of the best Kubernetes microservices architecture deployment practices is integrating robust security measures, such as role-based access control and data encryption.

Monitoring and Logging - You can deploy monitoring tools like Prometheus and Grafana for real-time insights.

CI/CD Integration - It helps to update the application rapidly, increasing its reliability.

Resource Optimization - You can use AWS Kubernetes microservices architecture for AWS Cost Optimization and resource usage.

Enhancing Manufacturing Operations with Modern Software Solutions

Modern software solutions are revolutionizing manufacturing operations, offering numerous benefits including real-time data processing, improved supply chain management, and enhanced production line efficiency and flexibility.

Real-time Data Processing and Analytics

- Immediate Insights: Real-time data processing allows manufacturers to gain immediate insights into production metrics, equipment performance, and product quality.

- Predictive Maintenance: Advanced analytics can predict equipment failures before they happen, reducing downtime and maintenance costs.

Improved Supply Chain Management

- Enhanced Visibility: Modern software provides end-to-end visibility across the supply chain, from raw material procurement to product delivery.

- Optimized Inventory: Inventory management systems utilize real-time data to optimize stock levels, reducing both excess inventory and stockouts.

- Supplier Collaboration: Improved communication and collaboration tools enable better coordination with suppliers, ensuring timely deliveries and reducing lead times.

Enhanced Production Line Efficiency and Flexibility

- Automation Integration: Integrating modern software with automation systems streamlines production processes, increasing throughput and reducing human error.

- Flexible Manufacturing: Software-driven production lines can quickly adapt to changes in product design or production volume, enabling more flexible and responsive manufacturing.

- Quality Control: Automated quality control systems analyze data from various production stages to ensure consistent product quality and compliance with standards.

Interested in Enhancing Guest Experiences Through Advanced Technology?

Explore How TRooTech's Cloud Engineering and DevOps Solutions Can Help

Challenges and Solutions in Software Modernization

Before signing off, it’s imperative to discuss a few significant challenges related to software modernization and their viable solutions that help you avert those issues.

- The Complexity in Migration - The development team may face the significant challenge of migrating a monolithic to the microservices architecture, dealing with complexity in designing, deploying, and managing the architecture.

- Data Management - Another key challenge is ensuring consistent data across distributed services.

- Security Concerns - Quality assurance and software testing teams have to secure and manage several microservices and access controls, which can pose difficulties.

- Performance Overheads - Developers may have to encounter performance issues due to increased inter-service communication, leading to latency.

- Cultural Resistance - At times, teams that are comfortable and accustomed to using monolithic architecture may resist the shift to microservices and Kubernetes.

Viable Strategies to Overcome These Challenges

- Adopting a Pilot Project - One of the best strategies is starting with a pilot project to slowly and gradually introduce Kubernetes and microservices architecture into the existing systems, enabling teams to adopt them with time.

- Implementing an Effective Data Strategy - It is crucial to implement consistent data patterns like CQRS and Saga for managing distributed data.

- Robust Security Measures - Implementing robust security measures like role-based access control (RBAC), network policies, and service meshes is necessary.

- Performance Optimization - Employ efficient inter-service communication protocols and monitor performance continuously.

- Cultural Shift - Foster a culture of continuous learning and collaboration through training and workshops.

Useful Tips to Ensure a Smooth Transition

- Comprehensive Planning and Analysis - First and foremost, you must have a clear understanding and develop a complete roadmap with defined milestones and success metrics.

- DevOps Practices - Migrating to Kubernetes architecture for microservices passes through CICD pipelines and automated testing practices to streamline the deployment process.

- Monitoring and Logging - Developers must use tools like Prometheus, Grafana, and ELK stack to maintain visibility and troubleshoot issues.

Conclusion

Automating, streamlining, and modernizing manufacturing operations using Kubernetes and Microservices Architecture yields significant benefits, including enhancement in the production line and increased scalability. Transformative technologies like artificial intelligence and machine learning algorithms, alongside real-time analytics, empower manufacturers to make informed decisions and faster innovation.

According to Verified Market Research, the application modernization market is estimated to reach $ 52.28 billion by 2030 at a CAGR of 16.8% between the predicted period 2024-2030. Similarly, Allied Market Research anticipates that the global microservices architecture market will reach $8,073 million by 2026, whereas another stat says that 90% of the organizations have adopted or plan to adopt it.

Application modernization software with Kubernetes and microservices architecture capabilities allows manufacturing units to leverage cloud infrastructure and computing solutions. However, it’s pivotal to evaluate the two most prominent cloud service providers and compare AWS vs Azure to choose the best based on your specific project and business needs.

By embracing these cutting-edge technologies, manufacturers can stay competitive and drive sustained innovation in the rapidly evolving market landscape, ensuring long-term success and relevance in the industry.

FAQs

Software modernization in manufacturing enhances efficiency, scalability, and flexibility. It enables real-time data processing, predictive maintenance, and improved decision-making through advanced analytics. By updating legacy systems, manufacturers can optimize operations, reduce costs, and stay competitive in a rapidly evolving industry.

The manufacturing industry implements microservices architecture to improve modularity, scalability, and resilience. Microservices allow for independent deployment and maintenance of services, enhancing flexibility and reducing downtime. This architecture supports continuous integration and delivery, enabling faster innovation and adaptation to changing market demands.

Kubernetes offers core benefits such as automated deployment, scaling, and management of containerized applications. It ensures high availability and resource efficiency, supports seamless scaling to meet demand, and provides robust orchestration and self-healing capabilities, enhancing operational efficiency and reducing downtime.

To implement microservices and Kubernetes in manufacturing, start with a phased approach:

- Assess and plan the architecture.

- Develop and test microservices

- Containerize applications.

- Deploy on Kubernetes.

- Integrate CI/CD pipelines.

- Monitor and optimize the system continuously.

Implementing Kubernetes and microservices architecture in manufacturing typically costs between $100,000 and 300,000, depending on factors like infrastructure requirements, software licensing, and professional services for deployment and maintenance. This investment covers initial setup, training, and ongoing support, aiming to enhance scalability, flexibility, and operational efficiency in the manufacturing process.